DSR high pressure wave plate bakelite anti-corrosion

Material: improved phenolic resin, rock wave fiber, no alkali, no short cut felt

Origin: Chuzhou Anhui

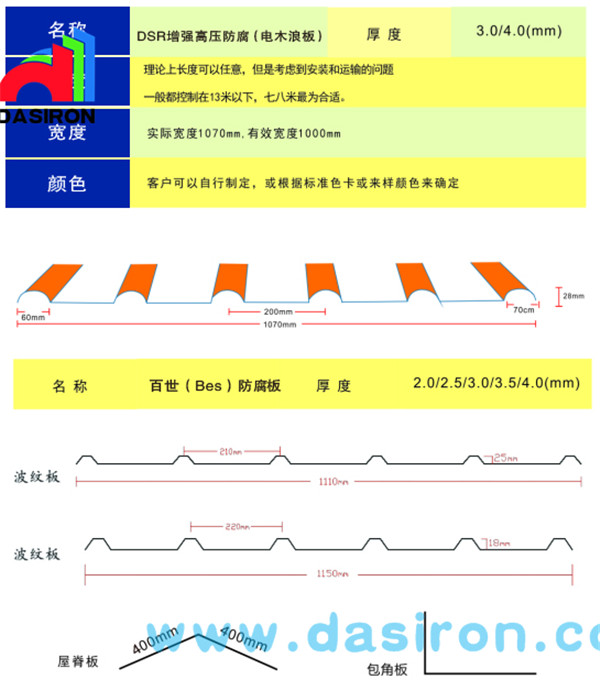

Specifications: TD1070 type, etc.

Thickness: 1mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm

Color: gray, blue, green, red, and so on (a variety of colors can be customized)

Tolerance to temperature: -55 C + + 250

Brand: Dragon

Purpose: designed for chemical corrosion resistance, good acid and alkali resistance, used in the chemical industry, such as the requirements of the chemical plant or chemical plant, foundry, etc.. The characteristics of high pressure corrosion bakelite composite plate enhanced DSR wave:

1, high strength

Bakelite anti-corrosion wave composite plate relative density is approximately 1.5, only carbon steel 1 / 5, tensile strength more than carbon steel, strength and high alloy steel is almost. In aviation, high pressure vessels and other products need to reduce the weight of the application, have a very good effect.

2, corrosion resistance

Bakelite anti-corrosion wave composite plate is excellent corrosion resistant materials, the high concentration of acid and alkali have better resistance. In the chemical industry, the application of anti-corrosion more.

3, insulation

Bakelite anti-corrosion wave composite plate is an excellent insulating material, can be used for the manufacture of insulator.

4, low thermal conductivity

Thermal wave bakelite composite plate corrosion rate is low, only metal 1/100, insulation material is excellent.

5, convenient design

Bakelite anti-corrosion wave composite plate can be flexibly designed according to the needs of a variety of products to meet the requirements of. Materials can be fully selected to meet the performance of the product.

6, anti condensation

The indoor relative humidity is lower than 80%, the inner surface of anticorrosive composite board material not dew.

7, excellent technology

Bakelite anti-corrosion wave composite plate to the shape of the product to the flexibility to choose the molding process. Process is simple, a molding

Guarantee period: 25 years

![[0000-00-00 00:00:00]

[0000-00-00 00:00:00]](/Upload/public/top22_02.jpg)

![[0000-00-00 00:00:00]

[0000-00-00 00:00:00]](/Upload/public/top22_02.jpg)